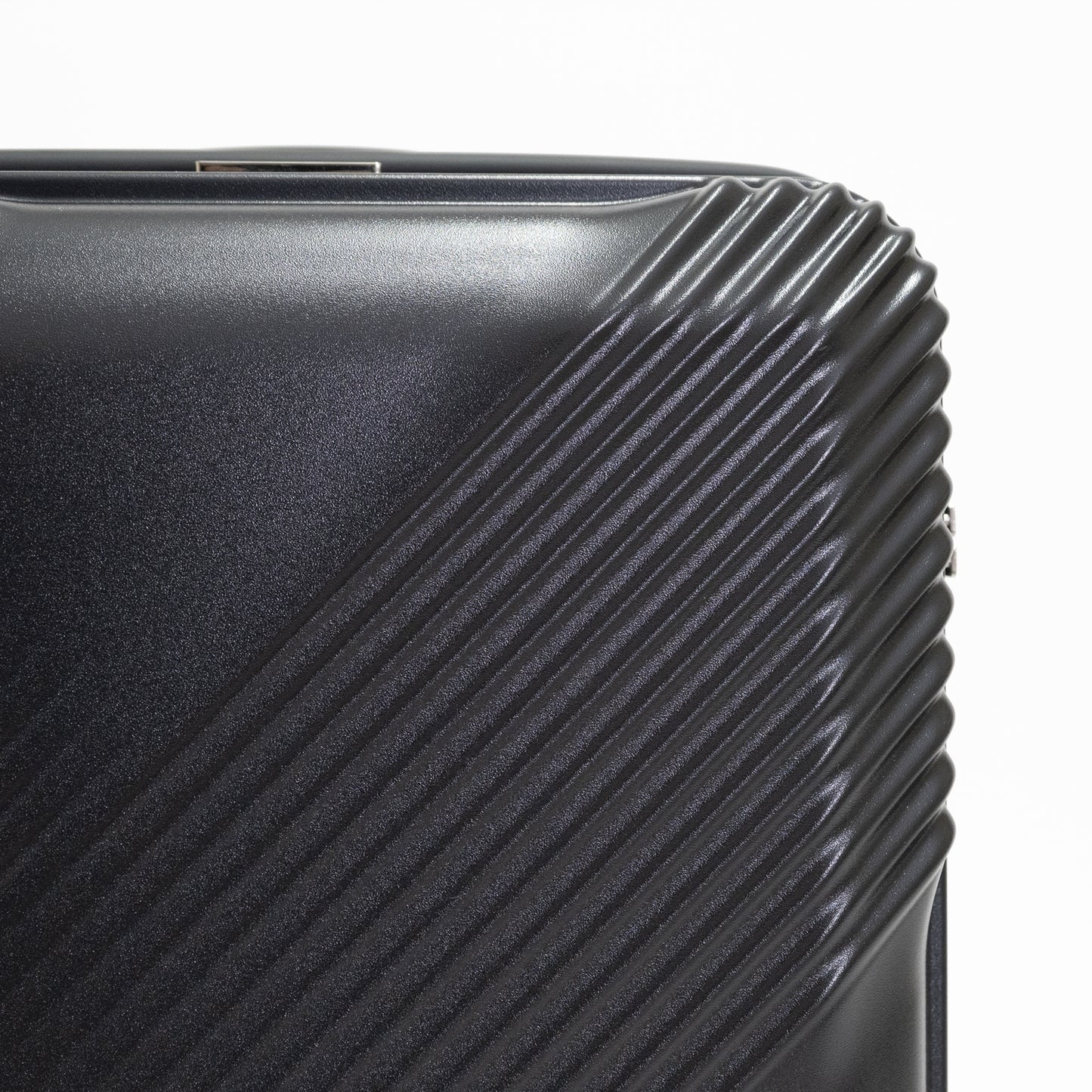

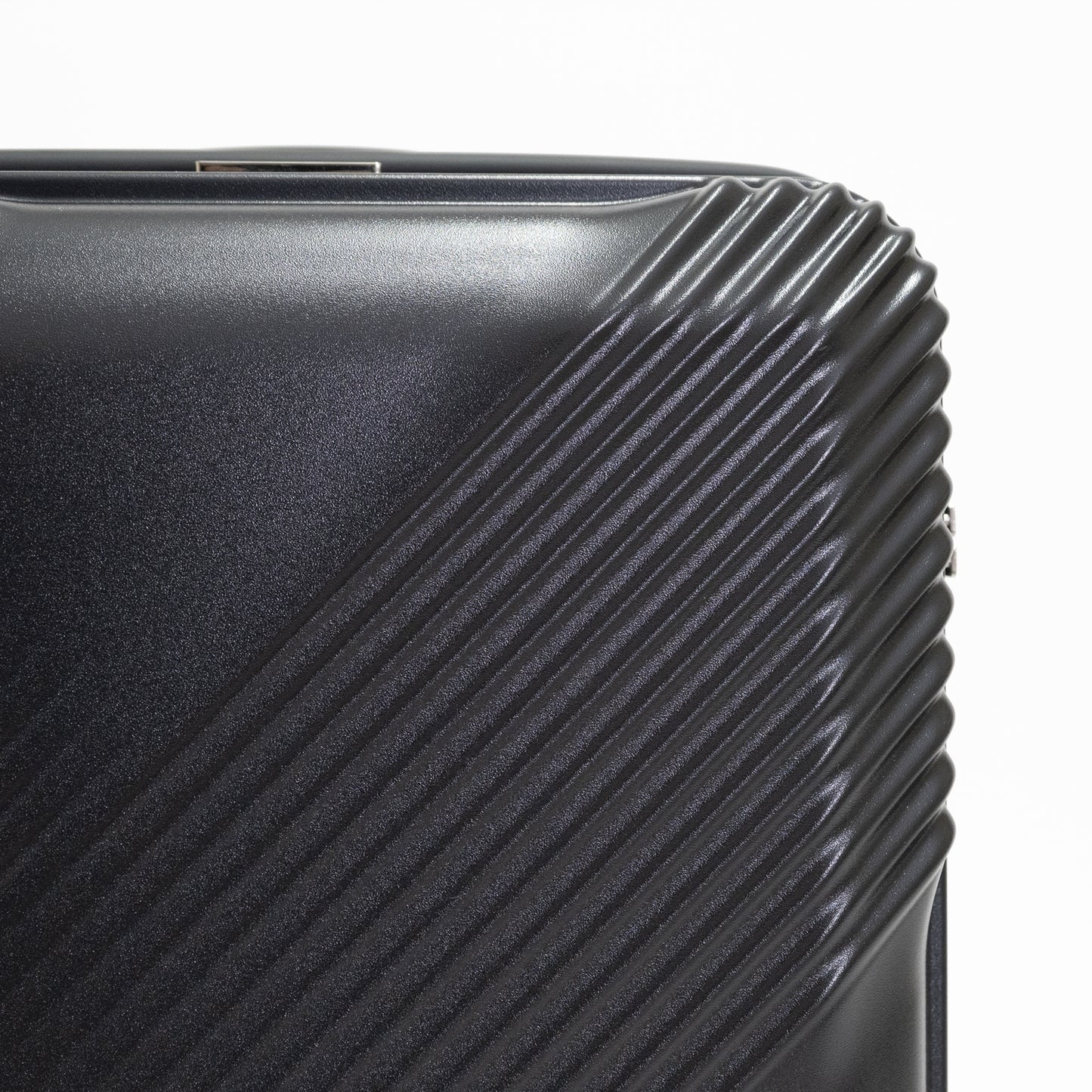

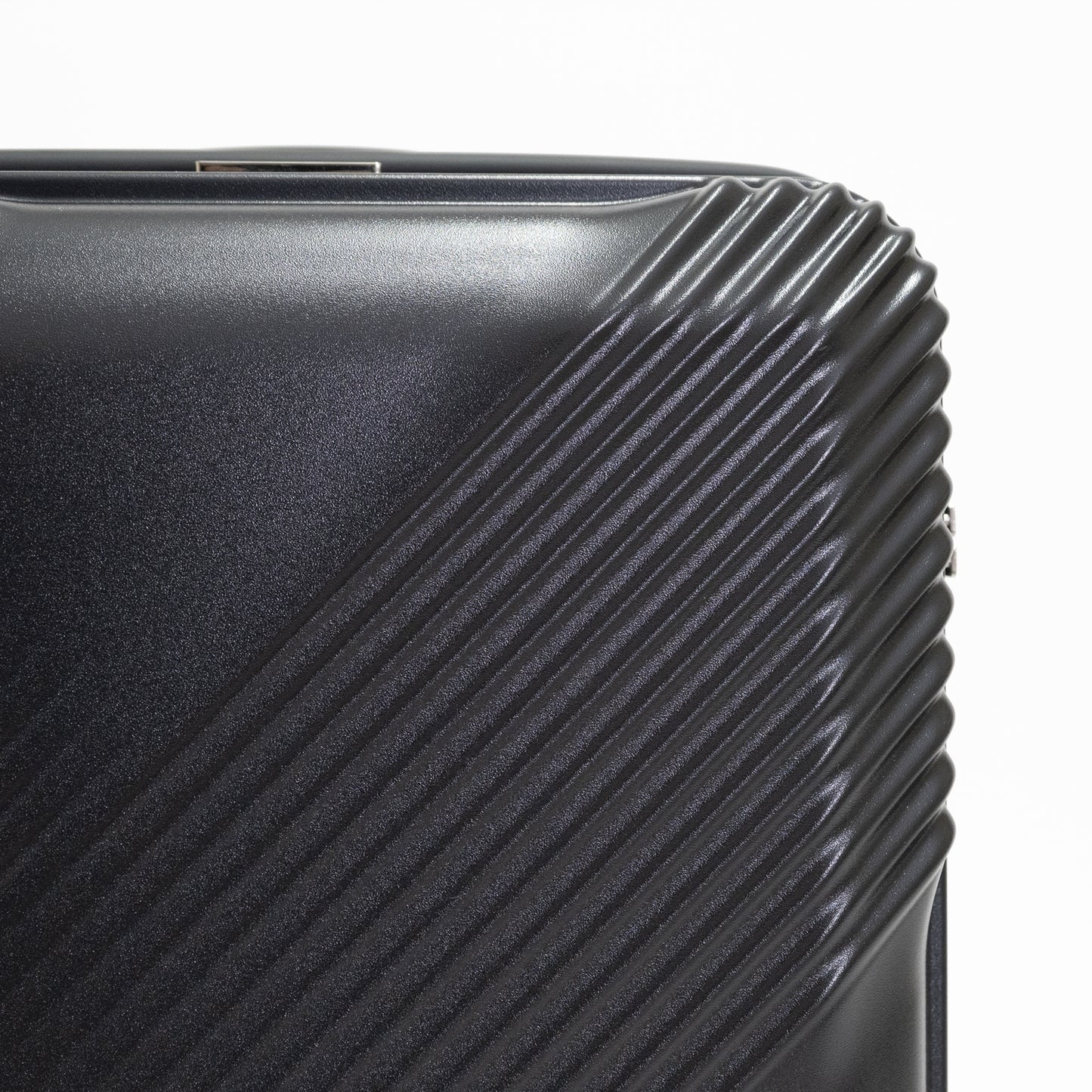

A recycled shell suitcase made from scraps generated during the manufacturing process of the main shell (the exterior of the suitcase) that are turned into chips and reused 100% for the main shell.

We conducted repeated testing until we were able to transform 100% of the scrap materials into new suitcases.

-

Glide 100% Recycled Shell Suitcase CABIN_No.5700177

Regular price ¥59,400Regular price -

Glide 100% Recycled Shell Suitcase MIDDLE_No.5700277

Regular price ¥62,700Regular price -

Glide 100% Recycled Shell Suitcase LARGE_No.5700377

Regular price ¥66,000Regular price

-

Body: 100% recycled materials

Scraps and other materials produced during the manufacturing process are crushed into small pieces and reused 100% as the main material.

-

Stop with one push

It can be easily operated with a switch at hand, and is equipped with a caster stop function to prevent unexpected rolling on buses, trains, or on slopes.

-

Silent wheels

It reduces noise while driving and the grooves in the tires reduce the sound of collisions with the ground, providing a noise-reduction effect.

Scrap materials generated during the manufacturing process of the main body shell (outer body of suitcases) are reused. Scrap materials in various shapes such as frames and plates are reused.

We stock scraps generated during production.

The scraps are then processed into chips, which are then crushed in a grinder into a size suitable for making suitcases.

Ace Luggage manufactures shells in a variety of colors, so the scraps are colorful. Multi-colored chips mix together like paint to create a deep graphite color.

The crushed scrap chips are stretched into sheets and then reshaped to create new suitcases.

We continue to maintain a system of producing recycled materials in our own factories.

STORY - The story behind development

Although we have been working to reduce the waste of materials since the company was founded, there were challenges in achieving 100% recycling. After much consideration and experimentation, we finally arrived at this product, which represents the culmination of Ace Luggage's technology and experience.

yezoLABO

Glide 100% Recycled Shell Suitcase CABIN_No.5700177

Share

yezoLABO

Glide 100% Recycled Shell Suitcase MIDDLE_No.5700277

Share

yezoLABO

Glide 100% Recycled Shell Suitcase LARGE_No.5700377

Share